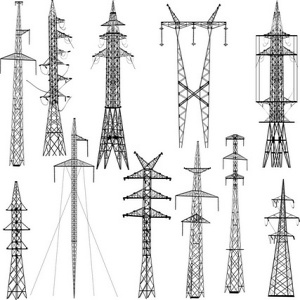

Lattice Frame Design: Adopts 3-legged or 4-legged angular/tubular steel lattice structures, with X/K-type cross bracing to distribute loads evenly—balancing high strength with lightweight efficiency (30% lighter than solid-frame alternatives).

Height & Span Optimization: Ranges from 20m to 100m (customizable for voltage needs), with tower spacing of 200–500m to accommodate power line sag and terrain variations (e.g., plains, hills, rivers).

High Load Capacity: Reinforced crossarms and cable attachment points to support multiple high-voltage lines (10kV to 500kV and above), with each tower designed to bear vertical loads (cables, ice) and horizontal forces (wind, seismic activity).

Terrain Adaptability: Modular base designs (gravity-based, pile-driven, or rock-anchored) to suit diverse soil conditions—from soft plains to rocky mountains—ensuring stability without excessive foundation costs.

Safety Integration: Equipped with lightning protection rods (compliant with IEC 62305), anti-climb barriers, and maintenance platforms to safeguard both the tower structure and workers.

Primary Structure: High-strength structural steel (Q235B/Q345B or ASTM A36/A572) for lattice frames and crossarms, sourced from top-tier steel producers (e.g., HBIS Group, Baowu Steel) to ensure structural integrity.

Corrosion Protection: Hot-dip galvanization per ASTM A123 standards (zinc layer thickness ≥85μm) to resist outdoor elements—including salt spray in coastal areas and humidity in tropical regions—extending service life to 30+ years.

Fasteners & Connections: High-tensile bolts (ISO 898 Grade 8.8) and precision-welded joints (AWS D1.1 compliant) to maintain stability under cyclic loads and environmental stress.

Compliance: Meets international standards such as GB 50017 (Chinese), ANSI/AISC 360 (American), and Eurocode 3 (European) for steel structures, ensuring compatibility with global power grid projects.

Long-Distance Energy Transmission: Connects thermal, hydro, wind, or solar power plants to urban and industrial load centers—transmitting high-voltage electricity over hundreds of kilometers with minimal energy loss.

Grid Interconnection: Links regional power grids to balance energy supply and demand, enhancing grid reliability and supporting renewable energy integration (e.g., wind farms in remote areas).

Industrial & Infrastructure Projects: Powers large-scale industrial parks, mining operations, and infrastructure developments (e.g., highways, railways) that require stable high-voltage energy supply.

Rural Electrification: Extends power access to rural and remote communities, bridging energy gaps with cost-effective lattice towers that adapt to low-population-density areas.

Coastal & Harsh Environment Deployment: Corrosion-resistant variants support power transmission in coastal regions, deserts, or high-altitude areas—withstanding salt, sand, and extreme temperature fluctuations.

Cost-Effectiveness: Lattice design reduces steel usage by 25–40% compared to solid towers, lowering manufacturing, transportation, and installation costs—recognized as a budget-friendly solution for large-scale grid projects.

Exceptional Durability: Hot-dip galvanization and high-quality steel ensure resistance to corrosion, wind (up to 250km/h), and seismic activity (up to Grade 8), minimizing long-term maintenance costs.

Modular Scalability: Prefabricated lattice sections enable easy customization of height, load capacity, and voltage rating—adapting to 10kV low-voltage to 1000kV ultra-high-voltage projects.

Efficient Installation: Modular components simplify on-site assembly, even in remote areas, reducing construction time by 30% compared to traditional solid towers.

Eco-Friendly: Low material consumption and compatibility with renewable energy projects align with global carbon neutrality goals, supporting sustainable energy infrastructure.

Annual Visual Inspections: Check for corrosion, loose bolts, or frame deformation—focusing on cable attachment points and crossarms subjected to constant load.

Semi-Annual Bolt Torque Checks: Verify tightness of high-tensile bolts to prevent vibration-induced loosening, especially in high-wind areas.

5-Year Corrosion Assessments: Inspect galvanized surfaces and touch up damaged areas with zinc-rich paint to maintain corrosion resistance.

10-Year Structural Load Testing: Conduct non-destructive testing (NDT) to evaluate weld integrity and load-bearing capacity, ensuring compliance with safety standards.